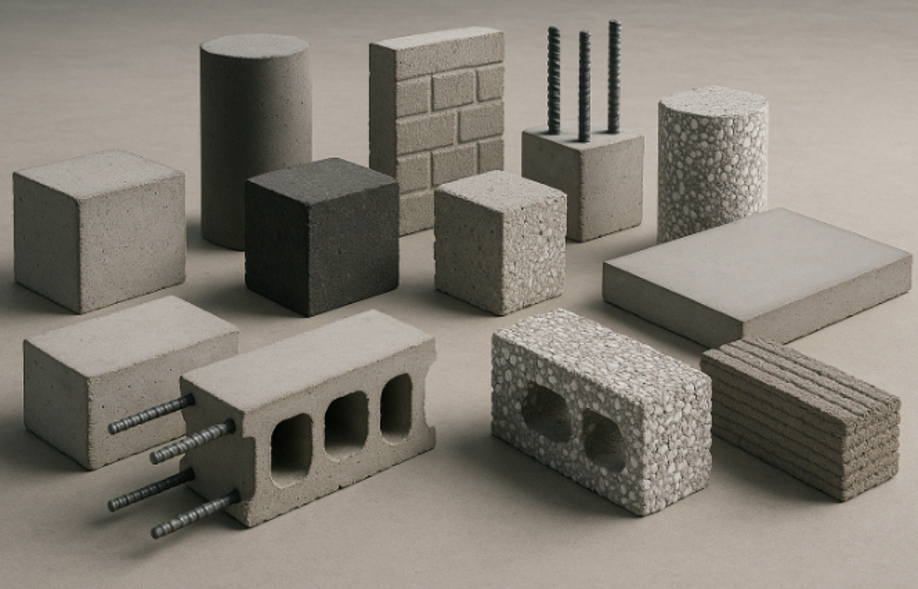

Concrete is one of the most important and commonly used materials in construction. It’s strong, long-lasting, and can be used in many ways, from building houses and roads to bridges and dams. But not all concrete is the same.

Each construction project needs a specific type of concrete. Knowing the features and benefits of each type helps engineers and Architects in Los Angeles choose the best one for the job.

In this blog, we’ll explore the most common types of concrete used in construction and what they’re used for.

1.Concrete Normal Strength

Normal Strength Concrete (NSC) is the most basic form, composed of cement, water, and aggregates like sand and gravel. It typically achieves a compressive strength of 20–40 MPa (megapascals) after 28 days.

Key Features:

- Easy to mix and pour.

- Ideal for pavements and residential projects.

- Relatively low strength compared to advanced options.

Common Uses:

- Sidewalks.

- Driveways.

- Residential flooring.

Normal Strength Concrete is a cost-effective choice for simple construction needs. It’s best suited for projects that don’t require high load-bearing capacity.

2. High-Strength Concrete

High-Strength Concrete (HSC) is engineered to have a compressive strength above 40 MPa. This is achieved by reducing the water-cement ratio and often incorporating additives like silica fume.

Key Features:

- Excellent durability and load-bearing capacity.

- Resistant to cracking and weathering.

- Requires careful mixing and curing.

Common Uses:

- High-rise buildings.

- Bridges.

- Heavy-duty industrial floors.

High-Strength Concrete is great for buildings and structures that need to hold a lot of weight. It’s strong, long-lasting, and works well in tough weather or heavy-use areas.

3. High-Performance Concrete

While similar to HSC, High-Performance Concrete (HPC) is designed not just for strength but also for specific performance characteristics such as Workability, Durability and Low permeability.

Key Features:

- Often includes supplementary cementitious materials (SCMs).

- Lower shrinkage and longer service life.

- Higher initial cost but better long-term value.

Common Uses:

- Marine structures.

- Tunnels.

- Precast elements.

High-Performance Concrete is strong and built to last, even in tough conditions. It costs more at first but saves money over time because it lasts longer.

4. Reinforced Concrete

Reinforced Concrete contains steel reinforcement bars (rebars), meshes, or fibers to improve tensile strength. Concrete is naturally strong in compression but weak in tension, and reinforcement solves this issue.

Key Features:

- Supports both compression and tension loads.

- Highly versatile and durable.

- Requires careful placement of rebars.

Common Uses:

- Beams and columns.

- Foundations.

- Parking structures.

Reinforced Concrete is ideal for structures that need extra strength to support heavy loads. It’s commonly used in foundations and support beams for buildings and bridges.

5. Prestressed Concrete

In Prestressed Concrete, steel tendons are tensioned before the concrete is poured, or post-tensioned after it sets. This process puts the concrete in compression, allowing it to handle greater loads and longer spans.

Key Features:

- Excellent for large spans and load-bearing structures.

- Reduces the need for thick slabs or supports.

- Requires specialized equipment.

Common Uses:

- Bridge decks.

- Parking garages.

- High-rise floors.

Prestressed Concrete is made stronger by stretching steel inside it. It’s perfect for big projects.

6. Precast Concrete

Precast Concrete is poured and cured in a controlled factory environment, then transported to the construction site for installation. It ensures consistent quality and reduces on-site labor.

Key Features:

- Precision manufacturing.

- Shorter construction timelines.

- Lower weather-related delays.

Common Uses:

- Wall panels.

- Staircases.

- Pipes and utility products.

Precast Concrete is made in a factory and then brought to the site, ensuring high quality and faster construction.

7. Lightweight Concrete

Lightweight Concrete uses lightweight aggregates such as expanded shale, clay, or pumice to reduce overall density. It typically has a density of less than 1920 kg/m³.

Key Features:

- Easier to handle and transport.

- Reduces structural load.

- Lower thermal conductivity.

Common Uses:

- Roof insulation.

- Non-load-bearing walls.

- Decks and floors in multi-story buildings.

Because of its reduced weight, Lightweight Concrete is ideal for projects that need to minimize the load on structures. It also offers better insulation and is easier to work with.

8. Self-Consolidating Concrete (SCC)

SCC flows and settles under its own weight without the need for vibration. It’s designed to fill formwork completely, even in tight or heavily reinforced areas.

Key Features:

- High fluidity and stability.

- Reduces labor and noise pollution.

- Offers a smooth surface finish.

Common Uses:

- Architectural concrete.

- Complex formwork.

- Repair works in congested areas.

Self-Consolidating Concrete (SCC) flows easily and doesn’t need to be vibrated. It’s great for tricky areas and complex forms, making it ideal for detailed projects.

9. Shotcrete

Shotcrete is sprayed through a hose at high velocity onto a surface, making it ideal for vertical or overhead applications.

Key Features:

- Strong bond with the surface.

- Fast application.

- Minimal formwork needed.

Common Uses:

- Tunnel linings.

- Swimming pools.

- Retaining walls.

Shotcrete is sprayed onto surfaces at high speed, making it perfect for vertical or overhead projects.

10. Roller-Compacted Concrete (RCC)

RCC has a drier mix than conventional concrete and is compacted using rollers. It doesn’t require forms or rebar in most cases.

Key Features:

- High strength and durability

- Cost-effective for large areas

- Fast construction.

Common Uses:

- Roads and pavements

- Swimming pools.

- Industrial yards.

Roller-Compacted Concrete is a strong and affordable choice for big projects. It’s quick to build and works well for roads, dams, and large industrial areas.

11. Pervious Concrete

Pervious Concrete has a high void content and allows water to pass through it, helping manage stormwater and reduce runoff.

Key Features:

- Environmentally friendly.

- Reduces hydroplaning on roads.

- Helps recharge groundwater.

Common Uses:

- Parking lots.

- Sidewalks and trails.

- Driveways.

Pervious Concrete is a great choice for environmentally conscious construction projects. It helps reduce water runoff and supports sustainable design in urban areas.

Final Thoughts

Concrete is a highly adaptable material, making it essential for many construction projects. Whether it’s a driveway or a dam, there’s a type of concrete suited for the job. New types of concrete are being developed to offer better performance, sustainability, and cost savings.

By understanding the strengths and limitations of each type, engineers and the Architect in Los Angeles, CA can make informed decisions that lead to smarter, more durable, and eco-friendly buildings.